The state of California produces 80% of the world's almonds, making almond products a key part of Central Valley's economy and landscape. To continue to produce a growing yield of almonds, sustainable practices are an essential part of the almond industry as a whole. These include ways to harvest and process almonds that are less taxing on the environment and workers, as well as more beneficial to the end consumer.

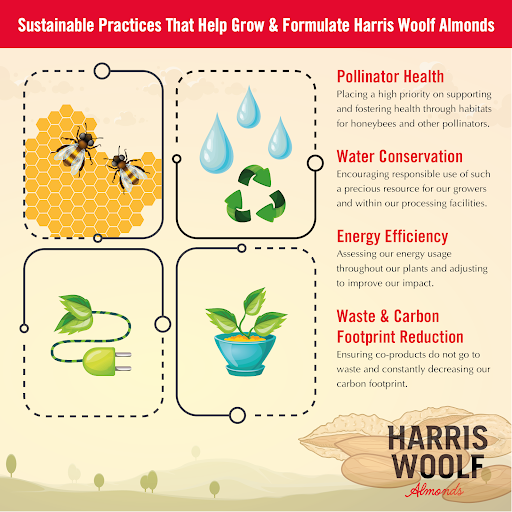

As the world's premier independent wholesale almond processor, Harris Woolf Almonds has become an industry pioneer with innovative solutions to grow and produce almond products. Our sustainable efforts are at the core of our brand and are integrated into our daily operations.

Let's dive into how our almond farmers and processing methods are making real changes in the United States agricultural industry with the specific techniques used to reduce environmental impact, improve productivity, and maintain a thriving industry.

The Almond Industry

In order to successfully grow an almond into a tall tree that has harvests of almonds in years to come, U.S. farmers need certain elements. Sunlight, soil, and water, as well as fertilizer, are the primary elements. However, over the years, farmers and businesses have discovered that becoming sustainable offers its own benefits to almond production.

There are several initiatives in the almond industry for becoming sustainable. This starts with the harvest of almonds and continues with processing and packaging. The Almond Board of California, an industry association, represents over 7,600 growers and 99 processors, providing support and creating a community that promotes a high level of innovation and sustainability.

Since 1973, the Almond Board of California has led nearly 700 research projects, advancing the industry as a whole with vital information, innovation, and resources. One of their recent efforts includes a pilot project that rewards "California almond growers for conservation practices that result in measurable climate impacts". These impacts include "increased soil carbon, reduced greenhouse gasses, improved water quality, and water use conservation".

With market expertise and the support of The Almond Board of California, almond processors like Harris Woolf Almonds are able to create healthy networks of growers, customers, and employees, promoting sustainable almond production.

Since 1989, HWA has prioritized sustainability by integrating positive impact into everything we do. Our impact report covers our current efforts and goals to commit to using less to produce more, but let’s break down our practices further starting with specific techniques to grow and harvest our almonds.

Almond Growing & Harvesting

The almond industry is a multifaceted supply chain that begins with growing and harvesting almonds. There are a lot of resources that go into growing almonds, and our farmers are faced with a variety of unique challenges.

The harvesting of California almonds starts in late July each year. The harvest season typically lasts for two to four months. The actual length of almond harvest is determined by any changes in the:

- Seasonal weather conditions

- Tree growth patterns

- Specific types of almonds, i.e., sweet almonds or bitter almonds

Almonds are harvested mechanically with tree shakers that knock the crop off of the almond trees. After they are removed from the tree, the almonds will remain on the orchard floor for 7 to 10 days to dry. After the almonds dry on the orchard floor and are swept into rows, sweepers pick them up, dump them into trailers, and they make their way to almond processors to be processed.

Many of our sustainability initiatives apply to the early steps of an almond's life cycle. Here are a few initiatives that guide the HWA growing and harvesting process.

Utilizing CASP

The California Almond Stewardship Platform (CASP) is a program led by the Almond Board of California that acts as a resource for almond growers and other key stakeholders. This platform encourages participation in sustainable growing efforts and builds a network of important information.

CASP participants are provided with key data on the almond industry. This includes data on:

- Orchard management practices

- Farm Sustainability Assessment (FSA) via the Sustainable Agriculture Initiative

- Bee Friendly Farming program in Pollinator Partnership

- Irrigation Continuum by the California Almond Board

- Nitrogen levels for almond crops

- Irrigation schedules for almond orchards

- Irrigated Lands Regulatory Program (ILRP)

- Irrigation and Nitrogen Management Plan (INMP)

- Responsible and efficient almond farming in CA

Tools that are available thanks to CASP include:

- Field mapping tools

- Nitrogen fertilizer calculator

- Irrigation system calculator

- Irrigation and nitrogen management planning

These tools and pieces of information are vital to almond farmers, particularly in California. With up-to-date almond data, almond harvesters and processors can improve yields and food safety standards. In addition, having self-assessments helps our growers learn more about how best practices can apply to their unique farms.

At HWA we are promoting participation in the online system to encourage our growers to be a part of industry advancements and to interact with valuable information and tools. Currently, about 38% of our grower base has completed the CASP assessment, and our goal is to increase the number to 75% by 2025.

Soil Management

Soil quality is a key part of maintaining high-yielding orchards. From salinity to nutrient management to cover crops, improving soil health is important for both environmental impact and for the efficient production of almond crops. CASP has become a key part of sharing innovative solutions to improve soil quality. On top of external resources, HWA's experience in the market has allowed us to reflect on the best practices for soil management. Woolf Farming (one of our founding farms), for example, has utilized effective tracking technologies to reduce the amount of tractor time needed to farm, resulting in higher soil quality and reducing our carbon footprint long-term.

Whole Orchard Recycling is another way HWA growers commit to both soil health and waste reduction. Chipping trees and reincorporating their nutrients into the soil sequesters carbon in the ground and minimizes the emission of greenhouse gases, promoting a positive impact all around.

Water Conservation

A single almond tree requires up to 44 inches of water each year, according to the University of California (UC). Some areas of Northern California receive up to 100 inches of rainfall a year, which makes almond growing suitable for the climate. However, in Southern California and Death Valley, the annual total rainfall is more like one inch a year.

Therefore, farming almonds in Sacramento and other Northern CA cities is necessary for water conservation purposes. This reduces the need to irrigate from reservoirs and aqueducts in order to provide enough water for the highest quality almond trees to grow and produce.

Extensive research has been conducted regarding tools and techniques for improving water conservation for almond trees in California. However, reducing water stress and providing more consistent watering even during droughts is also important. Drip irrigation typically resolves these issues by offering regular watering throughout the day and growing season and in any weather condition.

Harris Woolf Almonds continuously promotes the responsible use of this precious resource through water flow monitors, drip irrigation (as opposed to water-intensive irrigation systems), and the reutilization of wastewater. We even recapture water used in our almond processing facilities to be reused as irrigation water for our grower's crops.

Pollinator Health

The reality is, without honeybees and other pollinators, there would be no Harris Woolf Almonds. This is why we support and foster pollinator health by partnering with organizations such as Pollinator Partnership and Xerces Society. One of our founding farms, Woolf Farming is a pollinator health pioneer with over 200 acres of bee habitat for the year-round conservation of honey bees and pollinators.

Our 2025 goal is to have 75% of our growers Bee Friendly Farming (BFF) Certified.

Almond Processing

The importance of sustainability swiftly carries into the processing portion of almond production. Producing high-quality almond products such as almond flour, whole almonds, or almond butter takes a great deal of expertise and efficiency to provide a clean and safe end product. There are many resources as well as stakeholders to consider throughout this process.

Sustainable food processing eliminates excess and streamlines activities to be less taxing as a whole. Higher-quality products and efficiency overall can also increase the potential almond consumption for clients who rely on these valuable ingredient solutions.

The specific steps of almond production will differ based on the end product, but generally, you can expect the following:

HWA Sorting

Our Coalinga facility is the first step in the processing journey, where we focus on sorting, cleaning, shelling, and hulling our almonds. The pre-cleaning process involves methods to separate foreign material and product defects including any soil, grass, twigs, stones, or any almonds with insect damage.

The kernels then pass through a variety of machines that utilize different methods to remove the hull and shell of the almonds. Once removed, the individual kernels will be sent to the end of the line. The almond kernels are bulk packed into bins, consistently tagged with relevant information to keep track of the batch throughout the production process. The packages are randomly sampled for USDA grading purposes as well as internal grading efforts.

HWA Processing

After being sorted, the almond batches are sent to the processing plant, where they will be transformed into high-quality almond products. The rest of the process will depend on the end goal for the almond, but generally, the almonds are sent through a variety of optical sorting machines to separate the almonds based on size, customer specifications, and USDA grading parameters.

We offer both natural and blanched almonds for most of our wholesale product options. Further processing (for almond flour, protein powder, almond oil, and paste) will include roasting our almonds and milling them into a paste or pressing them into defatted cakes that result in almond oil and are grounded for almond flour and protein powder.

All of our production processes meet the standards of the FDA's Good Manufacturing Practices (GMP) and earn Safe Quality Food (SQF)'s highest rating.

Energy Efficiency within HWA Plants

Harris Woolf Almonds facilities prescribe energy-efficient practices. This covers water conservation for irrigation, as well as lighting management indoors. One of our biggest goals in 2025 is to have 50% of our company’s energy usage come from renewable sources.

Reducing Our Carbon Footprint

The carbon footprint for almond processing at Harris Woolf Almonds is on target to be cut by 25 percent by 2025. That means HWA will produce 25 percent less carbon dioxide into the environment as a result of manufacturing almonds.

Prioritizing Waste Reduction

Waste reduction is a major topic for almond processors. Finding ways to reduce waste in harvesting and manufacturing involves all parties. HWA doesn't let any co-products go to waste. This is key within the almond hulling and shelling process as our almond hulls are sold to local dairies as cattle feed and shells are sold as road base or bedding for cattle.

Utilizing the Best Processing Equipment

A huge contribution to our operational efficiency is our investment in world-class equipment. Harris Woolf's production line prioritizes safety and accuracy with some of the best methods to create the highest-quality almond products.

Committing to Inclusivity & Sustainability

As we continue to help formulate high-quality food and beverage products, our sustainability efforts stand at the core of our business. Our recent status as a Certified B Corporation™ reflects this commitment to continue making a positive impact on our community. It's important for food and beverage manufacturers to invest in high-quality products that come from clean practices and trustworthy brands.

Since 1989, Harris Woolf Almonds has worked with local growers to produce sustainable food products to act as an innovative ingredient solution. These products include:

- In-shell almonds

- Almond butter and almond paste

- Natural almonds

- Almond protein powder

- Almond flour

- Sweet almond oil

The HWA product lines contain sustainable almonds grown up to the highest quality and USDA standards. Check out our Inaugural Annual Report to learn about HWA goals for 2025 and the significant differences we are making in sustainable agriculture.